When everyone else seems to go straight home after their shifts, some people continue to work even after the sun has already set. Working during the night might be hazardous, but it cannot be avoided. This fact rings especially true in the construction industry. Since every second counts in construction projects, companies strive to make the most out of the 24 hours in a day. The longer a construction project takes, the more money is being spent. Roadside construction also needs to be completed quickly so as not to obstruct the flow of traffic for long. Given all these reasons, every professional in the construction industry aims to complete the project at hand as soon as possible, even if it means working nights.

Construction zones are filled with all sorts of hazards, which only increase at night. Of course, working at night means the absence of daylight, and poor lighting and low visibility are a sure recipe for accidents. For this reason, construction workers have to make use of artificial lighting during the nighttime. Companies should also develop an effective lighting plan for construction sites to prevent accidents caused by low-light conditions.

Importance of Adequate Lighting on Construction Sites

Because of our circadian rhythms, or our internal 24-hour sleep-wake cycle, we are naturally accustomed to be active during the day and to rest during the night. At night, the human body releases melatonin or the so-called hormone of darkness. This hormone regulates our sleep-wake cycle and subsequently impacts our alertness. Lack of alertness can lead to errors, poor judgment, and, in turn, possible accidents. If working during the night cannot be avoided, having adequate lighting on construction sites can counter the effects of melatonin and reduce the likelihood of accidents.

Ergonomics does not only pertain to furniture design; it also concerns the source of lighting in the workplace. Some examples of poor light ergonomics are flickering light, glaring light, insufficient light, and poorly distributed light. Working under poor lighting can result in eyestrains, headaches, and awkward posture, all of which can worsen over long periods of exposure to poor lighting. Inadequate lighting might also adversely affect employee morale, which can consequently impact productivity. In other words, poor lighting can create a stressful and unhealthy working environment for employees. It can thus worsen the well-being of construction employees in the long run.

With sufficient lighting, employees can see everything they are working on, so they can get the job done with the utmost precision. As a result, adequate lighting can increase overall productivity and prevent employees from doing rework. It can also improve the quality of the project as it helps employees avoid committing mistakes or miscalculations.

Last but not least, having inadequate lighting negatively affects the overall safety of the construction site. Low visibility poses hazards to safety, such as struck-by hazards and improper handling of heavy machinery. In poorly lit settings, minor to fatal accidents are bound to happen since machine operators and other employees cannot clearly see their surroundings. Moreover, in roadside construction projects, there’s a high chance that employees and motorists might get involved in traffic accidents due to low-light conditions. With proper lighting, however, accidents due to low visibility can be avoided.

Types of Lighting for Construction Sites

Before forming an effective lighting plan for the job site, construction employers and employees should know about all of the kinds of temporary lighting. This way, they can determine the appropriate type of lighting source that they need for the job.

There are only a handful of temporary lighting options available for nighttime construction use. Nevertheless, these lighting options are effective and functional as they are designed to be. The most commonly used lighting sources for construction sites include balloon lights, equipment-mounted lights, portable light plant towers, warning lights, and temporary roadway lighting. Each of these types can be combined with one or more of the other types for sufficient construction site lighting.

1. Balloon Lights

Balloon lights look exactly like how they sound. This type of light fixture is composed of a spherical or balloon-shaped translucent material, which surrounds one or more high-intensity lamps. This translucent balloon material can disperse light and reduce its glare. Some balloon lights even have reflective coatings to direct beams downward. Because of their design, balloon lights can evenly distribute light rather than generate a concentrated beam. Compared to other types of lighting sources, balloon lights can emit just the right amount of illumination with less glare.

2. Equipment-Mounted Lights

Working with heavy machines, such as excavators and concrete pavers, calls for a great amount of light. With adequate lighting, machine operators can see the path ahead and correctly maneuver their machines. Moreover, they can avoid accidentally hitting other people in close proximity to their machines.

Some heavy machines already have headlights or factory-installed lights. However, most of these lights do not generate beams that are bright enough for the task at hand. Some built-in lights of machines also produce excessive glare, while others cannot be adjusted toward the areas that need lighting.

For this problem, equipment-mounted lights are the best solution. Some portable utility lights or light heads can also be installed on equipment with the use of compatible lighting mounts. These lighting systems can provide a particular area with sufficient light while employees operate heavy equipment. They can come in handy in certain situations wherein it isn’t practical to supply lighting throughout a large area. Another great thing about equipment-mounted lights is they can supply continuous lighting, which eliminates the need for machine operators to set up lighting repeatedly.

3. Portable Light Towers

Most models of portable utility lights for construction sites are composed of plant towers mounted on trailers. A portable light tower typically features wheels, which allow users to move these lighting systems from one location to another. It also consists of multiple light bulbs attached to a mast arm, which can be adjusted to a desired height and position. This mast arm is usually mounted on a trailer with a generator set to power the lighting system.

In many cases, portable light towers alone can provide the work area with the minimum level of illumination required for nighttime construction. Because of this, they can emit glare that might obscure the line of sight of those exposed to the light. To prevent this from happening, users should position their light towers properly. This way, they can directly focus the illumination toward the work area. It’s also important to note that certain construction tasks require supplemental lighting in addition to light towers.

4. Warning Lights

Construction sites located near roadways should have warning lights in place. Setting up these lights can warn oncoming vehicles against driving toward the construction zone. Some warning lights can be mounted on the sides of machines to alert other construction workers to the presence of dangerous equipment.

5. Temporary Roadway Lighting

While streetlights already exist on most roads, road construction zones require a greater amount of lighting than what streetlights produce. Because of this, temporary roadway lighting is often necessary for road construction projects. This type of lighting system consists of a light fixture installed on a temporary pole. Normally, temporary roadway lighting requires the expertise of a professional lighting designer to hardwire the light fixture to an electrical system.

Levels of Illumination

Developing an effective lighting plan for the construction site requires determining the exact amount of illumination needed in the area. To make the task simpler, the National Cooperative Highway Research Program (NCHRP) has created the Report 498: Illumination Guidelines for Nighttime Highway Work. The NCHRP is responsible for identifying the problems affecting the design, planning, construction, maintenance, and operation of highways in the U.S. With this program’s illumination guidelines, construction companies can provide their work zones with an appropriate level of illumination.

These illumination guidelines are divided into three categories based on the minimum levels of lighting for specific nighttime construction activities. Moreover, these guidelines make use of foot-candles as the standard unit of illumination. Each foot-candle is equal to one lumen per square foot or 10.764 lux.

1. Level I

For construction tasks that require a low level of accuracy, Level I illumination is sufficient. This level requires 5 foot-candles or 54 lux, and it is ideal for job sites with slow-moving equipment. While Level I illumination is suitable for all work areas, it is mostly used for road closures, flagger stations, and lane closure tapers.

2. Level II

Workers who need to complete tasks with a moderate level of accuracy should have Level II illumination, which requires 10 foot-candles or 108 lux. This level of illumination is ideal for areas with construction equipment and for tasks such as milling, asphalt paving, and concrete work.

3. Level III

Lastly, Level III requires 20 foot-candles or 215 lux for construction projects that need a higher level of visual acuity. This level of illumination is important in tasks such as pothole filling, pavement repairs, joint repairs, and equipment installation.

Creating a Lighting Plan

As with all kinds of projects, creating a plan first can go a long way. Planning the lighting layout for construction sites can help you point out the area’s lighting needs. It can also prevent you from purchasing excessive lighting systems, which can serve as unnecessary expenses. With an organized lighting plan, a job site can have the proper level of illumination needed for safe and efficient construction work. Moreover, those driving through a construction zone can be guided accordingly with an optimal lighting layout. Most importantly, a proper lighting plan can improve the overall safety of construction workers and other people in or around the work zone.

1. Identify the Work Activities

When planning your lighting layout, the first thing you need to do is to determine all of the activities in the work zone. In your lighting plan, you have to note the entire construction process, from start to finish. You can then incorporate that information and the NCHRP’s illumination guidelines in your lighting plan.

For instance, those working near slow-moving equipment should work with a Level I illumination of 5 foot-candles. 10 foot-candles, on the other hand, are required for concrete removal tasks. For tasks that require the utmost precision and care, such as filling cracks in the pavement, the area should have a Level III illumination of 20 foot-candles.

2. Find out the Areas That Need Illumination

The next factors that you have to consider in your lighting plan are the areas that require illumination and their specific lighting needs. By finding out the specific lighting needs of areas, you can have an easier time positioning each of your lighting systems.

For this task, you have to draw up a scale layout of the work area. This scale drawing should include the locations of workers and construction equipment as well as the specific activities taking place in those locations. Moreover, the scale layout should contain the status of activities and other important pieces of information, such as existing street lights, flagger stations, lane drops, and road obstructions.

3. Choose the Appropriate Types of Lighting and Their Locations

After determining all of the construction tasks and areas that require lighting, it’s time to choose the proper types of lighting sources. While there are only a few commonly used types of lighting systems for construction, you still need to carefully select the right types for the project. In addition to this, you need to consider how these light fixtures will be powered. You might want to check if your lighting sources will be needing generators, power grids, or fuel systems.

The next thing you have to do is to identify the best placements of your lighting systems, including your primary and supplemental lighting sources. These lighting sources should not obstruct the way of construction and transportation. Referring to the NCHRP’s illumination guidelines can greatly help you effectively position your lighting sources.

4. Finalize the Layout

After ever lighting system is in place, you should check the entire lighting layout of the area via walk-through and drive-through. By doing so, you can find out the effectiveness of your lighting layout from the perspectives of both the drivers and the construction workers. Additionally, you might want to check if your state’s department of transportation requires the use of a photometer to measure and verify the levels of illumination on the job site.

Finally, after examining the area’s lighting layout, you can make the modifications and improvements as necessary. Every modification and improvement you do should be recorded for future reference.

Choosing the Right Lighting Sources

Improving the overall safety and efficiency of construction sites calls for the proper lighting sources and layout. Adequate illumination is especially useful for nighttime construction wherein low visibility can bring about a number of hazards. However, lighting systems alone are not enough for optimal workplace lighting. There also needs to be an effective lighting plan so that you can create an optimal lighting layout for the area and make the most of your lighting systems.

When it comes to the visibility of construction workers, high-visibility apparel, in addition to proper lighting, can also help maintain workplace safety. These garments can protect workers against hazards by reflecting light back to the source and consequently making wearers more visible to drivers and machine operators.

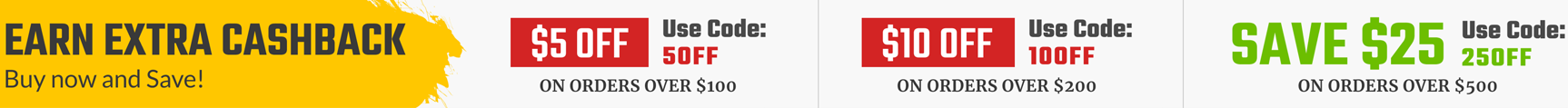

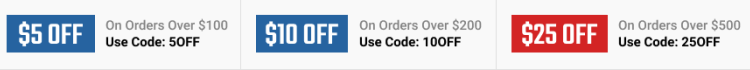

Investing in the right lighting sources means investing in safety and efficiency. It also entails finding out the best manufacturers of lighting equipment. With a vast array of lighting manufacturers to choose from, finding durable and quality products can get a tad challenging. Fortunately, Engineer Warehouse has narrowed down the best brands in the lighting industry. The industrial lighting systems and components that these brands have made will surely provide you with long lamp lives, bright illumination, and effective construction site lighting.