In order to survive day after day, having a job is a necessity. Being employed allows us to afford our basic needs and luxuries, and it also provides us with something to do most days of the week. Having a trade is thus both necessary and unavoidable, but it does not change the fact that hazards are an inevitable part of any job.

Even working in offices exposes employees to some forms of hazards, such as repetitive strain injuries, slipping, and falling. However, work environments that are filled with more dangerous elements present an entirely different level of hazards. These work environments can be construction zones, healthcare facilities, laboratories, oil and gas fields, and many more. Heavy machinery, toxic substances, and other harsh elements abound in these locations, but that doesn’t mean accidents can’t be prevented. Safety is indeed a top priority in any line of work, and one way to achieve this is to follow OSHA standards.

- I. Understanding OSHA Standards

-

II. Top 10 Most Violated OSHA Standards

- 1. Fall Protection

- 2. Hazard Communication

- 3. Scaffolding

- 4. Control of Hazardous Energy (Lockout/Tagout)

- 5. Respiratory Protection

- 6. Ladders

- 7. Powered Industrial Trucks

- 8. Fall Protection – Training Requirements

- 9. Machine Guarding

- 10. Personal Protective and Lifesaving Equipment – Eye and Face Protection

- III. Choosing the Right PPE According to OSHA Standards

Understanding OSHA Standards

If it had not been for the grisly workplace fatalities during the mid-20th century, the Occupational Safety and Health (OSH) Act would not have been formed. In the early 1970s, the U.S. Congress proposed the OSH Act because of the 14,000 occupational fatalities that were happening annually. Additionally, there were over 2 million job-related disabilities and 300,000 cases of job-related diseases. After almost a century of employees being exposed to the dangers of the industrial age, President Richard Nixon signed the OSH Act into law in December of 1970. On April 28, 1971, the Act became effective, thus giving birth to the Occupational Safety and Health Administration (OSHA).

Right after the inception of OSHA, the administration established standards for five industries with the worst safety hazards: lumber and wood milling, marine cargo handling, roofing and sheet metal work, mobile homes, and meat industries. Today, however, virtually every industry and its workers are covered by OSHA standards. To be more specific, OSHA standards cover all employers and employees in the private sector, state and local government agencies, and federal government agencies. The most well-known OSHA standards at present cover maritime, agriculture, general industry, and construction.

Simply put, OSHA standards are designed to protect workers against workplace hazards. They also serve as criteria for determining whether employers are complying with the OSH Act laws. According to these laws, employers are responsible for maintaining the overall safety of work environments and mitigating serious workplace hazards. Moreover, these laws state that employees have the right to work in an environment where they have access to safety and health protection.

The main responsibility of OSHA is to enforce its standards to mitigate the hazards in regulated industries. One of the ways the administration carries out this responsibility is through random inspections. These random safety inspections have been proven to help reduce work-related injuries. Apart from enforcing standards, OSHA is also responsible for providing regulated entities and workers with assistance and training.

II. Top 10 Most Violated OSHA Standards

![]()

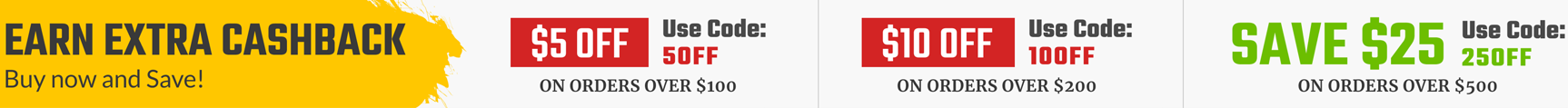

There are a variety of consequences when employers violate OSHA standards. Employers have to pay thousands of dollars in fines, and this amount increases as the gravity of the violation worsens. Besides OSHA penalties, employers are bound to pay legal damages when employees get injured or even killed on the job. Moreover, they can face charges of criminal negligence resulting in the deaths of workers. Companies that violate safety and health standards will also be placed under scrutiny and be seen in a bad light by clients, partners, and the community in general. Of course, the biggest consequences of OSHA violations are tragic accidents resulting in injuries or even casualties. The cost of human life is, needless to say, irreparable and beyond compensable.

Most work-related injuries and deaths are easily preventable, yet a great number of industries continue to violate OSHA standards. Because of this, OSHA releases a list of the most frequently cited violations each year. This list serves as a useful guide for identifying the most common shortcomings of employers across various sectors when it comes to workplace safety. This way, every employer can take the necessary steps to prevent job-related injuries. The list also serves as a reminder for employees to do their individual roles in maintaining overall safety. So without further ado, here are the top ten most cited OSHA violations of 2019 to early 2020.

1. Fall Protection

For years, the standard 1926.501, which covers the duty to have fall protection, remains undefeated in topping the list of the most cited OSHA violations. Falls are the leading causes of work-related injuries. Employees can tumble down from overhead platforms and other high places, such as elevated workstations and roofs. They can also fall into trenches or through the holes in walls. Furthermore, this standard applies to work environments in which employees can fall onto dangerous machines. While it’s imperative to follow all of the OSHA standards, it also won’t hurt to take extra precautionary measures to protect employees against falls.

Under the fall protection standard, employers are required to set up guard rails, toe boards, or covers on floor holes. These safety rails can also be placed around elevated platforms that are at least six feet high. Marking holes on the floor with pennant flags or other marking tools can also prevent employees from falling into them. Additionally, there should be stair railings and safety harnesses, lines, and nets in areas with fall hazards.

2. Hazard Communication

The second most violated OSHA standard is the Hazard Communication standard 1910.1200, which applies to employees exposed to chemicals. This standard requires manufacturers and importers to evaluate the specific hazards of chemicals and to make labels and safety data sheets containing these hazards. This way, employees and customers can readily access and easily understand the information about certain chemical hazards.

It’s also the responsibility of employers to train their employees on how to correctly handle and deal with hazardous chemicals. Moreover, they need to provide their employees with the proper protective equipment, like masks, coats, and gloves.

3. Scaffolding

Over 2 million workers work on scaffolds, which are temporary platforms used to raise construction employees. When scaffolds are not well-constructed, chances are they’ll break or collapse, causing employees to fall over. It is estimated that over 70% of scaffold-related accidents involve employees tripping over broken scaffolds and getting struck by falling scaffolds. That’s why employers and employees alike should follow the scaffold standard 1926.451.

This standard aims to protect workers against injuries and deaths caused by falling from suspension scaffolds. Under this standard, fall protection equipment such as guard rails should be placed on scaffolds raised at least 10 feet above ground level. Additionally, the standard aims to protect employees against electrocutions while they work on scaffolds near power lines. It also includes how to use, maintain, and inspect mobile scaffolds.

4. Control of Hazardous Energy (Lockout/Tagout)

Any machine is subject to regular maintenance and servicing. During these activities, however, the machines might unexpectedly and suddenly turn on because of their stored energy. Some examples of these situations are steam valves automatically starting up, jammed conveyors suddenly working, or wires of equipment shorting out. Another example is an employee accidentally activating a machine without knowing that a fellow employee is simultaneously working inside that machine. These situations can result in serious or even fatal injuries, such as burns, electric shocks, crushes, and amputations. More often than not, electricians, machinists, and craftspeople are at great risk of experiencing these hazards.

Because of this, employers should follow the lockout/tagout standard 1910.147, which aims to control the hazardous stored energy of equipment. The most important element of this standard is the use of energy control devices to prevent a machine from suddenly running. According to this standard, employers should require workers to place labels on machines during maintenance. These labels should warn others against operating the machines that the labels are tagging. These machines include those that run on pneumatic, thermal, hydraulic, electrical, chemical, mechanical, and other sources of energy.

Machines powered by electricity are breeding grounds for arc flash hazards, which can cause severe burns. To be well-protected against arc flash hazards, those working around these machines should wear flame-resistant vests or flame-resistant shirts.

5. Respiratory Protection

Factories, warehouses, and other workplaces across the U.S. are filled with air pollutants, such as dust particles, fumes, smoke, mist, and sprays. When exposed to such elements, especially for long periods, the well-being of employees can be adversely affected. In fact, air pollutants have become the leading causes of lung cancer, infections, and other severely debilitating or fatal diseases. Those who work in confined, poorly-ventilated spaces with low oxygen levels are also at risk of developing various respiratory diseases. For this reason, employers must comply with the respiratory protection standard 1910.134. Doing so can significantly reduce these hazards and prevent a significant number of illnesses and deaths.

Basically, the respiratory protection standard involves the use of respirators in the workplace. Respirators are designed to protect workers from inhaling hazardous contaminants in the air. There are also respirators made to remove pollutants from the air by filtering out particles and purifying the air at the same time.

6. Ladders

Using ladders is the most common cause of fall injuries in many workplaces. Because of this, OSHA made a separate section on this under its fall protection standard. This section covers employers across all sectors.

There are many ladders used in various industries, but the main types of ladders used by most employees are portable ladders and fixed ladders. OSHA provides several recommendations on using these two types of ladders under the standard subpart 1926.1053 about stairways and ladders. Basically, this standard subpart covers the clearance of every step, rung, and cleat of ladders as well as the minimum weight capacity of ladders.

7. Powered Industrial Trucks

Next on the list involves perhaps the most apparent hazard on job sites yet continues to be overlooked by some companies. This hazard concerns powered industrial trucks, also known as forklifts or lift trucks. Make no mistake about it—these machines seem dangerous at first sight, and they are dangerous while in use. Accidents can happen as employees handle heavy loads while maneuvering these machines. However, when employees and employers comply with the powered industrial trucks standard 1910.178, these machines will surely be a lot safer to use.

The best precautionary measure to prevent forklift-related accidents depends on the type of trucks being used as well as the type of job site on which they are used. In general, employers should ensure that the forklift drivers they hire should be competent enough to operate their powered industrial trucks. With this in mind, employers should provide powered industrial truck operators with relevant training. Employees working with or around these machines should also wear high-visibility apparel, such as high-visibility vests and shirts. By wearing these garments, forklift drivers can easily see their fellow employees and, in turn, steer their forklifts away from them.

8. Fall Protection – Training Requirements

The eighth most frequently cited violation is related to the first one on the list. This violation involves the standard 1926.503, which refers to the training requirements for fall protection. It requires training employees on how to determine the sources of falling hazards in the workplace and how to use fall protection equipment. After completion of this training, employers are required to prepare a written certification record containing the list of workers who have completed the training. In addition to this, the standard states that employers should designate specific roles to employees in the prevention of fall hazards.

9. Machine Guarding

Probably one of the most frightening accidents that can happen to any machine operator is getting injured by machines. Each year, machines cause over 800 deaths and 18,000 injuries, such as crush injuries, lacerations, abrasions, and amputations. Among all occupational injuries, amputation is one of the most crippling and most severe. Hands are essential tools of the trade, and losing them might also mean losing the ability to work directly with machines. That said, it’s an absolute requisite for employers to put the appropriate safeguards around machines. Under the machine guarding standard 1910.212, the guarding devices that employers can use include adjustable, self-adjusting, interlocked, and fixed guards.

10. Personal Protective and Lifesaving Equipment – Eye and Face Protection

Getting blinded while working is something that any of us wants to avoid. However, many industries continue to violate the eye and face protection standard 1926.102. In fact, every year, thousands of workers are blinded due to job-related accidents. These accidents typically involve toxic chemicals, flying particles, vapors, and many other substances. If employers had properly enforced the standards in their workplaces, these accidents could have been easily avoided.

Eye and face protection should be worn at all times when employees are exposed to chemical, radiological, mechanical, and environmental contaminants and hazards. Welders and woodcutters are also required to wear eye and face protective gear. This gear includes face shields, safety glasses, and goggles.

Choosing the Right PPE According to OSHA Standards

OSHA standards mainly exist to guide employers and employees in keeping the job sites free of hazards and accidents. However, there are a huge number of OSHA standards created, so learning all of them might be overwhelming or admittedly tedious. That’s why employers should find out the standards under which their organizations fall. This way, they can narrow down the list of standards that they need to understand and follow. Moreover, determining the hazards present in their workplaces is key to taking the necessary safety measures. Whatever measure your company needs to take, the compliance and participation of both employers and employees are crucial in maintaining the overall safety in workplaces.

Most workplace accidents can be easily prevented when employees wear appropriate personal protective equipment (PPE). This equipment includes apparel and accessories that are designed to keep wearers safe on the job. However, with a lot of manufacturers of PPE out there, it can be challenging to choose the right one for employees to wear. Luckily, Engineer Warehouse has sourced top-quality high-visibility and personal protective equipment from the best manufacturers. Comfort and quality are some of the most important factors in choosing the best PPE, and these garments and accessories offer just these things.